|

|

|

|

|

|  |

Overview:-

KISHAN turbine pumps are of rugged, heavy-duty construction designed to successfully operate in a multitude of applications such as pumping from water source including wells, lakes, cooling ponds, tanks, rivers and oceans. These applications include raw water intake, liquid transfer, cooling water circulation, booster service, storm water, flood control, marine, process services, volatile fluids, condensate, fuel pumps and mine dewatering. KISHAN turbine pump applications are found in a variety of markets including: urban and rural municipal water, irrigation, chemical processing, primary metals, petroleum, power plants, mines, food processing, offshore platforms, and more.

Features:-

- Parameters of vertical pumping applications require the units be available in a variety of pumping configurations to meet user needs. Fairbanks Morse meets these demands by providing pump bowls from V-6,V-8,V-10 in diameter. Turbine bowls can be staged in series to produce the necessary discharge pressures.

- Materials of construction include cast iron, bronze, stainless steel and G.I Pipes or other machineable materials. Wear rings are available to provide a renewable surface.

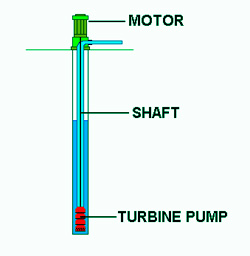

- Open line shafts allow the product to lubricate the shaft bearings. Enclosed line shafts can provide external water flush, oil, or grease-bearing lubrication. Threaded or flanged column and line shaft assemblies are available in both short and deep-set applications.

- Drive shafts extending through the discharge head can be sealed using either packing or mechanical seals. A wide range of mechanical seal designs are available along with an assortment of packing box designs, including those for high-pressure applications. Fairbanks Morse also offers an array of discharge head designs, including cast iron or fabricated steel construction, above-or below-ground discharge, and flanged or plain-end discharge connections.

- Vertical pumps require a minimum of NPSH since the lowest impeller is submerged in the liquid. However, even when the system design does not provide enough NPSH, vertical turbine pumps can be supplied with its own reservoir or "pot". In this way, submergence required by the first stage impeller can be achieved to ensure reliable performance.

- Vertical turbine pumps can be driven by vertical monoblock motors, vertical solid-shaft motors, or through right-angle gears by an internal combustion engine, steam turbine, or horizontal motor. operate with gas kate and wind-mill.When vertical monoblock drivers are used, impeller-to-bowl clearances can be maintained with an adjusting nut located at the top of the driver. When vertical solid-shaft drivers are utilized, impeller clearance is regulated with an adjustable coupling.

|

Application:-

Pump Size 75*62 mm |

Pump Head |

Eng H.P |

Bore Size |

Pump R.P.M |

Discharge L.P.M(Approx) |

50/100 |

8/10 |

150/200 |

1600/1700 |

500/600 |

50/100 |

10 |

150/200 |

1700/1800 |

600/750 |

100/150 |

10/12 |

150/200 |

1600/1700 |

500/600 |

100/150 |

12 |

150/200 |

1700/1800 |

600/750 |

150/200 |

12/14 |

150/200 |

1600/1700 |

500/600 |

150/200 |

14 |

150/200 |

1700/1800 |

600/750 |

200/250 |

14/16 |

150/200 |

1600/1700 |

500/600 |

200/250 |

16 |

150/200 |

1700/1800 |

500/550 |

Pump Size 100*100 mm |

Pump Head |

Eng H.P |

Bore Size |

Pump R.P.M |

Discharge L.P.M(Approx) |

50/100 |

12 |

200/250 |

1600/1700 |

700/800 |

50/100 |

12/14 |

200/250 |

1700/1800 |

750/850 |

100/150 |

14 |

200/250 |

1600/1700 |

650/750 |

100/150 |

14/16 |

200/250 |

1700/1800 |

750/800 |

150/200 |

16 |

200/250 |

1600/1700 |

650/750 |

150/200 |

16 |

200/250 |

1700/1800 |

800/900 |

|

|

|

| |

Details of Diesel engine horse power |

Feet |

Engin Hoew Power |

50 ft to 100 ft |

8-10 horse power |

100ft to 150 ft |

10-12 horse power |

150ft to 200 ft |

12 horse power |

200ft to 250ft |

12-14 horse power |

250ft to 400ft |

14-16 horse power |

|

| |

|

|

|

|

|